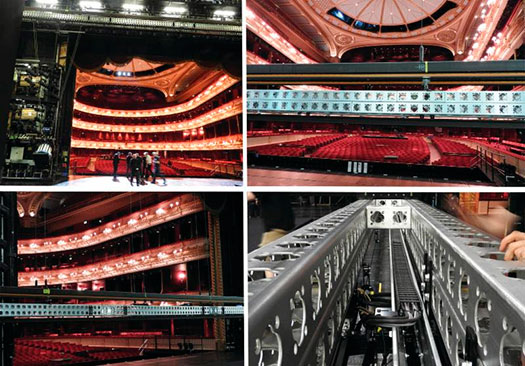

Track expert Triple E’s ‘universal building system’, ModTruss, has provided an incredibly strong and versatile solution to fly a powerfully bright 18kW Arrimax HMI head in an arc over the stage for the world premiere performances of ‘Morgen und Abend’ at London’s Royal Opera House.

The opera Morgen und Abend is by Austrian composer Georg Friedrich Haas and is a co-commission and co-production between The Royal Opera and Deutsche Oper Berlin. Award-winning Norwegian author, poet and playwright Jon Fosse provided the libretto.

The production team approached Hertfordshire-based ‘theatre magicians’ Lamp & Pencil to devise a solution for flying the Arrimax HMI head in a moving yoke across the stage to represent the path of the sun.

The vertical movement of the lamp is achieved with the existing flying system at the venues. The horizontal movement is realised with tracks on a frame with a carriage driven by existing point hoists.

The ModTruss sections were combined with Triple E’s Unibeam, carriers and other standard components and required very little custom metalwork. Triple E managed the project, designed and built the mechanical elements.

“For the mechanical side of the project, ModTruss was our first thought,” said Lamp & Pencil’s Robin Barton. “ModTruss not only gave us flexibility for adjusting the length but also incredible strength which allows for fewer pick up points. We were very impressed with the ease of assembly and the strength and flexibility offered.”

Cable management required some careful consideration. The team had to get DMX data, accessory power and lamp power to the head as well as find somewhere to put a 50kg ballast unit.

“After investigating our options, we selected the Igus e-chain product to provide the required cable management, protection and segregation at a low weight and with very quiet operation,” Robin continued. “When large cables are carrying around 90A at 225V DC, you need to be sure that they are well ventilated, sufficiently supported and do not bend too tightly – the cable chain achieves all of those. The cable chain runs in a trough which has to remain straight and level to ensure correct operation. Fixing this to traditional truss could have been tricky but the holes in the ModTruss made positioning adjustable brackets easy and the flat sides held them straight.”

The ends of the chain were terminated with bespoke enclosures containing connectors to allow quick connection and disconnection of all the lines.

“With the ModTruss structure we were able to produce a gap of 1′ between two runs of laminated 6-inch ModTruss which fitted our ballast perfectly,” Robin explained. “The ballast is positioned at the stage left end where it is close to the proscenium bridge which allows a technician to access the controls if required.”

The ModTruss system, best described as ‘full size Meccano’, features a lightweight aluminium construction and a repetitious hole pattern and the ability to fix on all 6 sides, meaning applications are practically unlimited. The ModTruss product line lends itself to create endless configurations using standard accessories, and makes ideas that once took extensive custom design and fabrication to be constructed incredibly simply, easily, and speedily.